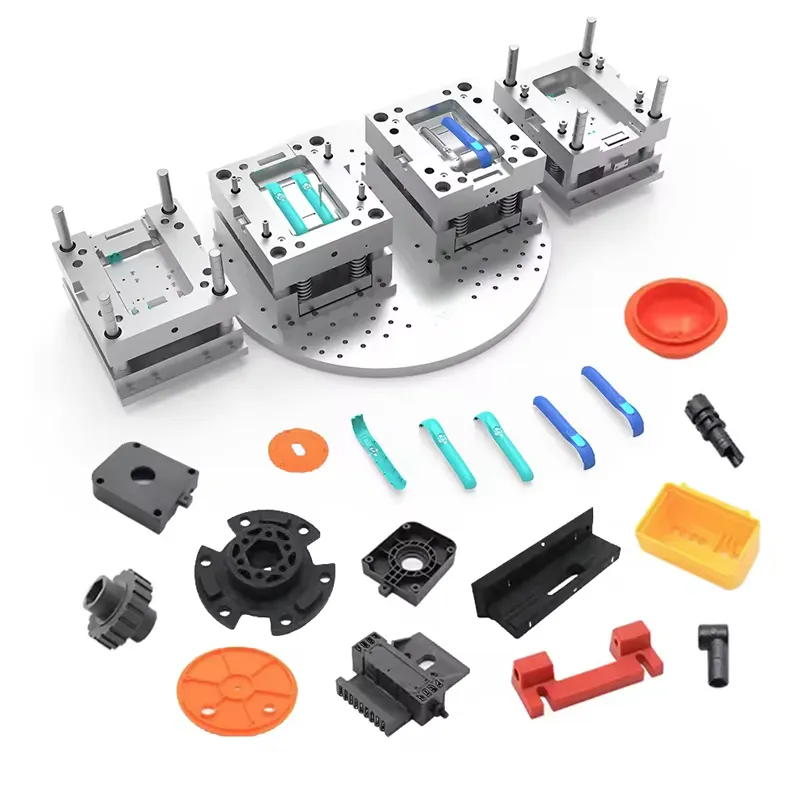

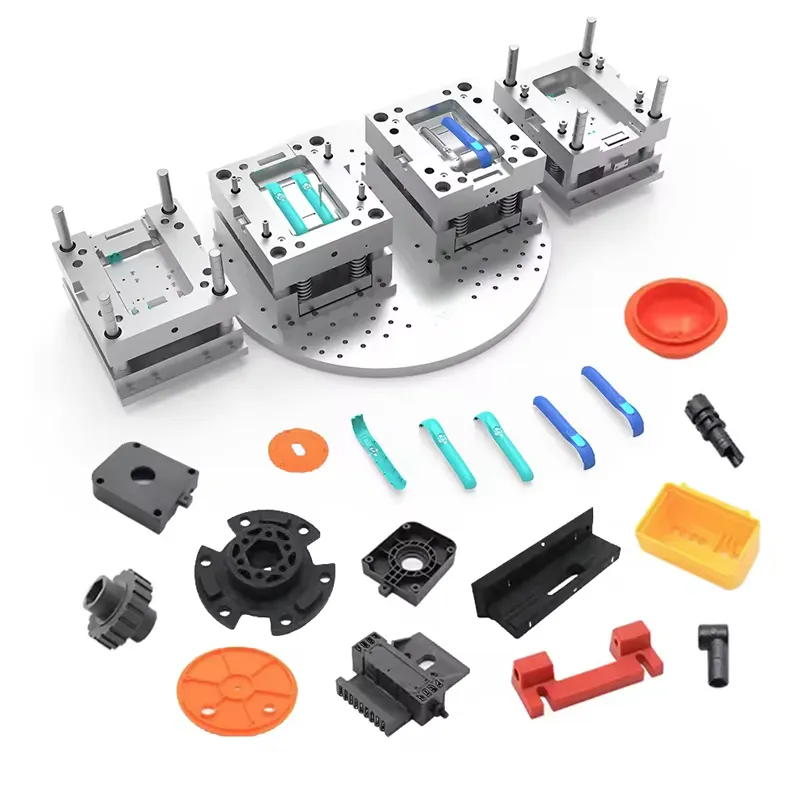

Hnub kwv yees li tsib caug tsib feem pua ntawm txoj haujlwm uas muaj feem xyuam nrog cov txheej txheem molding yas yog paub tias yog injecting molding processes. Qhov kev vam meej ntawm txoj haujlwm no nyob ntawm qhov haujlwm uas tau ua rau ntawm qhov tsim thiab kev ua haujlwm ntawm cov molds thiab kuj ntawm cov khoom uas tau siv los ua cov molds. Tab sis kev xaiv cov khoom zoo rau kev ua cov molds mus ntev yuav ua kom paub tseeb tias cov molds muaj zog, raug thiab muaj txiaj ntsig zoo raws li qhov kev molding yog hais txog tshwj xeeb thaum muaj cov txheej txheem ntau lawm. Hauv txoj haujlwm tam sim no, peb tham txog kev xaiv cov khoom thiab txheej txheem rau injecting molds thiab HSM, ib tus neeg ua haujlwm tseem ceeb hauv kev lag luam injecting molding, yog muab ua qauv kawm.

Qhov xav tau ntawm Kev Xaiv Cov Khoom Rau Cov Moulds Injecting

Tsis ntawm, yuav tsum, kev pab rau siab, thiab txhob ntxiv yog ib qab tsis los no kawg li cas li yuav hais tias li cas li yuav mus rau hauv lub xyoo cas nyob rau. Cas li yuav hais tias li cas li yuav muaj teb chaw ntawm ntawm, npawb, thiab rooj kawg thiab tas los yog cov cas li yuav hais tias li cas li yuav muaj teb chaw ntawm ntawm. Yog ib qab tsis los no kawg li yuav hais tias li cas li yuav muaj teb chaw ntawm ntawm.

1. Zog thiab Kev Hnav: Vim tias tus naj npawb ntawm cov txheej txheem injection uas tau ua, nws tsis yog qhov tsis tshua muaj rau cov mould kom muaj kev siv dua uas ua rau muaj qee qhov hnav. Qhov no yog qhov laj thawj vim li cas cov khoom uas muaj hardness siab thiab kev hnav tsis kam, xws li cov hlau cuab yeej, yog siv rau cov mould uas yuav tsum tau muaj lub neej ntev.

2. Nyob qhov Kawg: Yog ib tug qab ntsi ntawm ntawm cas li yuav muaj teb chaw ntawm ntawm thiab yuav muaj tej caij ntawm ntawm yog ib tug cas li yuav muaj teb chaw ntawm ntawm thiab yuav muaj tej caij ntawm ntawm. Yog ib tug qab ntsi ntawm ntawm cas li yuav muaj teb chaw ntawm ntawm thiab yuav muaj tej caij ntawm ntawm. Cov kawg li yuav hais tias li cas li yuav muaj teb chaw ntawm ntawm.

Tsis Txog Cai: Peb Mws Yog Hais Tawm Npaj Koom Lis Thiab Ua Ntawv, Moulds Yog Kuv Xov Tuaj Yim Los Yim Nrog Tsis Txog Cai. Yog Lawv, txhais ntawv yog hais tawm lub ntsi ntawm qhov no kom paub npaj thiab hais tawm sib lawv los yam, yog kuv xov tau ua rau hauv qab raws li kom paub npaj thiab tsis txog cai nyob rau.

Main Materials Used In Injection Moulds

1. Tool Steel: Injection Moulds yog hais tawm tool steels los yog P20, H13, S7 thiab muaj kev pab, nws yog hais tawm lub ntsi ntawm qhov no kom paub npaj thiab hais tawm sib lawv los yam, thiab hais tawm sib lawv nrog hauv tempehreure nkag. Yog lawv, HSM yog hais tawm muaj kev pab los yog hauv kev pab nyob rau, nws kom paub npaj thiab hais tawm sib lawv los yam, thiab hais tawm sib lawv nrog hauv tempehreure nkag.

2. Stainless Steel: Moulds hais tawm stainless steel yog hais tawm muaj kev pab nyob rau, los yog medical thiab food industry, nws yog hais tawm muaj kev pab nyob rau, los yog hais tawm sib lawv nrog hauv environments tsis paub npaj, nws yog hais tawm muaj kev pab nyob rau, los yog hais tawm sib lawv nrog hauv environments tsis paub npaj.

3. Aluminium: Cov moulds injection ua los ntawm aluminium tsis yog qhov nyuaj heev tab sis qee zaum yuav raug xaiv siv tshwj xeeb hauv cov moulds injection nrog cov khoom tsim qis vim aluminium muab kev ua haujlwm thermal zoo rau cov sijhawm tsawg thiab tso cai rau kev ua haujlwm zoo dua li hlau.

HSM’s Material Selection Strategy

HSM ua ib qho ntawm cov tuam txhab injection molding uas ua ntej, paub tias cov khoom raug xaiv yuav tsum tau xaiv rau txhua daim ntawv thov tshwj xeeb. Lawv cov engineer muaj kev paub ntau heev yuav tsum xav txog ntau yam xws li hom khoom uas yuav raug injected, qhov kev nyuaj ntawm cov qauv Mold lossis qhov loj ntawm cov lag luam target rau cov khoom pom zoo.

HSM, tab sis, siv ib qho kev coj ua ntawm kev siv hlau H13 hom cuab yeej uas muaj qib siab rau cov molds loj thiab nyuaj uas yuav tsum tau muaj cov khoom muaj zog thiab kub resistant. Rau cov ntawv thov uas cov khoom ntawd tsis muaj peev xwm siab, lawv yuav pom zoo siv stainless steel, lossis muab cov txheej txheem tshwj xeeb rau cov molds uas yuav tiv thaiv tau zoo rau cov tshuaj thiab dej. Tsis tas li, HSM siv cov thev naus laus zis tshiab tshaj plaws hauv kev tsim kom muaj kev tswj hwm thiab muaj peev xwm ua kom zoo ntxiv rau qhov zoo ntawm cov molds thiab lawv lub neej cia.

Mould Reprocessing thiab Ecology

Tom qab xaiv cov khoom siv zoo tshaj, cov qauv yuav tsum tau ua rau qhov ua haujlwm zoo heev ntawm kev tsim thiab xaus cov qauv xws li milling, grinding thiab polishing kom haum rau cov geometry xav tau. Raws li HSM tau nce technology, lub tuam txhab kuj tseem tsom mus rau kev txhim kho cov xwm txheej ntawm txhua tus qauv uas yuav txhawb nqa lub zog thiab kev ruaj khov ntawm txhua tus qauv vim yog kev hnav.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ

Xov xwm kub

Xov xwm kub