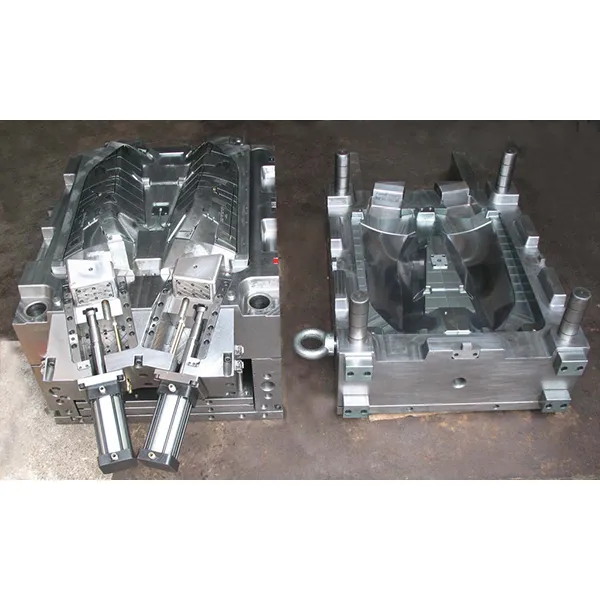

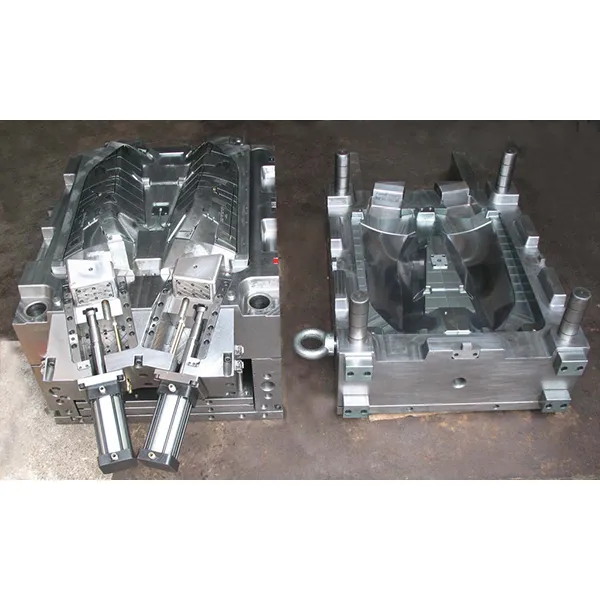

Injection molding as a method for producing plastic parts in bulk is very popular. However, in the case of multi cavity plastic parts, the design and manufacture of injection molding tools requires skilled labor and advanced technology. HSM The Company has all solutions for precision molding. Engineering and HSM injection molding designs is advanced for producing complex parts. These molds allow good quality product, cost savings, and less time to market.

Engineering for all aspects of design for complex shapes

The study of injection molds for complex plastic components is important for the performance and quality of the part. Instead, HSM emphasizes the use of highly developed computer tools to develop injection molds that are capable of creating complex external contours and even internal cavities incorporating features like undercuts, minimal wall thickness construction, and multiple materials combinations. During the development processes molding cycle, cooling, and part removal processes are analyzed to design a mold that works effectively while making quality parts.

Custom Manufacturing Tooling

For injection molds in which intricate plastic components are involved, the correct materials must be selected. HSM uses supply materials such as hardened steel and aluminum alloys which are formulated based on the type of plastic components to be produced. These materials withstand the rigors of heating and pressuring during the injection molding process.

Custom Manufacturing Tooling

To achieve perfection, great attention to the process parameters must be given. HSM’s arsenal encompasses advanced CNC machinery, electrical discharge machining, and surface treatment technology. Such molds manufactured by HSM are sure to meet incredibly low tolerances and high standards in terms of surface quality. This is of the utmost importance when more complex parts with many functional features are required to be fabricated.

Quick Prototyping and Validation

Quick Prototyping and Testing facilitate the design and fabrication of injection molds of plastic components by making sure at all times the final outcome is compliant with the requirements. At HSM, rapid injection mold design and testing is carried out with the aid of 3D printers. This strategy helps in diagnosing and correcting all errors concerning the design, reaping the optimal performance of the mold, therefore reducing the time taken for production.

The step by step detailed execution of the processes of design and making of injection molds for complex structures of plastic components has tackled the challenges of quality, precision and cost standardization. HSM is well endowed in this domain, through cutting-edge techniques, new designs, materials and casts are offered. Essentially, in their confidence, HSM provides support to organizations in the deformation of advanced levels of plastic parts and coping with the highest specifications, making them a favorable injection mold company.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ

Hot News

Hot News