SuperTech Mould Limited: Precision Injection Moulding Solutions

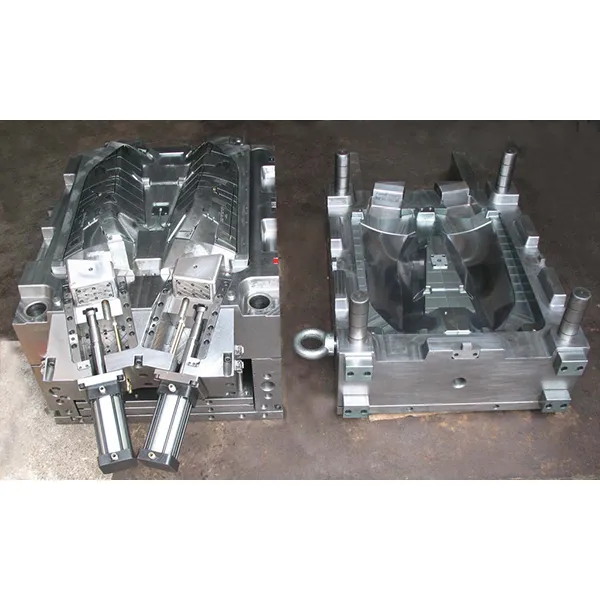

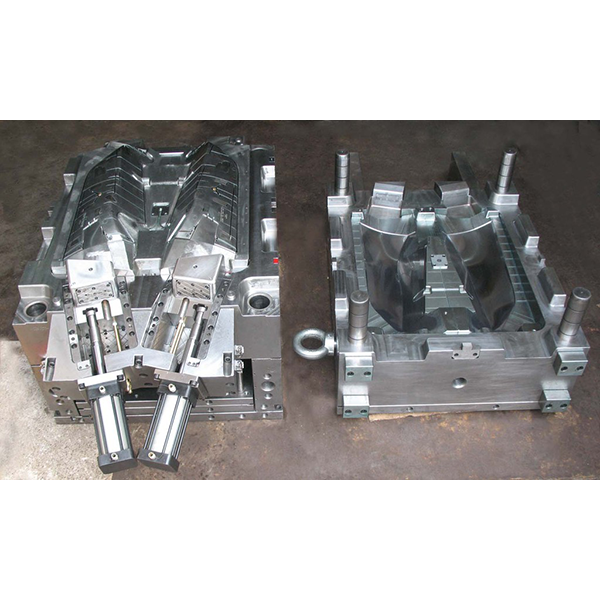

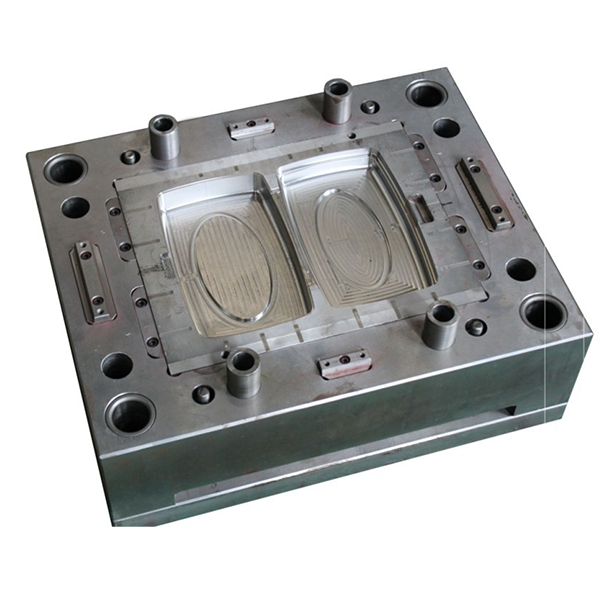

SuperTech Moulds Limited is an expert in providing custom injection moulding solutions for manufacturers. We have the best technology and a team of professionals who can produce quality molds that will not only optimize production but also enhance the performance of your products. Be it automotive, medical or consumer electronics moulds you need; SuperTech Moulds Limited can deliver them as per your requirements.

Our machines are advanced while our attention to detail is second to none so that each produced mold meets even the most stringent tolerance levels set by clients. We use good materials and follow strict quality control procedures which ensure that all our molds are reliable and consistent in performance. Trust us with your project involving plastic injection molding because this is what we do best.

The twenty-first century manufacturing industry requires efficiency as its cornerstone; hence at SuperTech Moulds Limited we understand this need very well indeed too. In order for us achieve high efficiency levels during production processes’ we work hand in hand with our customers towards realizing such goal by optimizing their tooling systems as well as manufacturing techniques thereby resulting into quicker lead times together with reduced costs involved per unit produced. With continuous improvement initiatives being implemented always in every phase of our operation right from initial design consultations up until post-production supports rendered thereafter; It means that you shall be able to attain greater profitability heights within your business organization through increased productivity rates achieved during various injection moulding operations carried out over time.

At SuperTech Moulds Limited, customer satisfaction is paramount therefore excellence has no limit when it comes to serving clients throughout their projects’ lifetime cycle management stages either! Our designers are always ready assist whenever called upon while technicians provide onsite support where necessary thus making sure that all client needs are met promptly without compromising on quality whatsoever. Expect nothing less than perfection from us since we possess both skills & knowledge required so as meet such expectations accordingly.

Choose SuperTech Moulds Limited partner success drive precision manufacturing operation in the injection molding industry. We offer comprehensive services and our commitment is customer satisfaction therefore we remain the best choice for any complex project concerning this field. Contact us today and know more about what we can do towards realizing your business goals

Get A Quote

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ