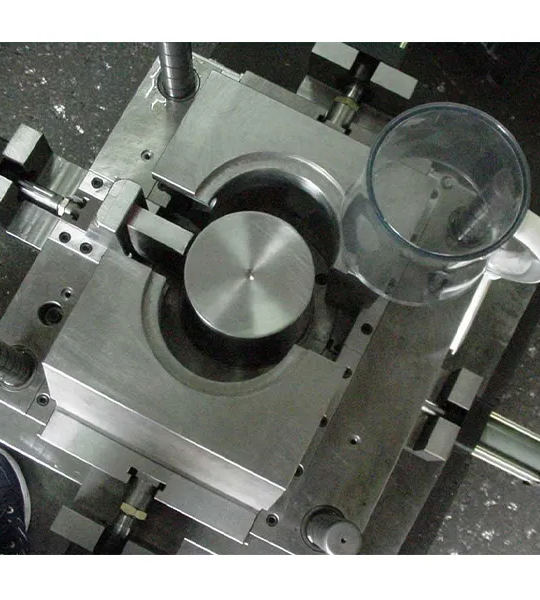

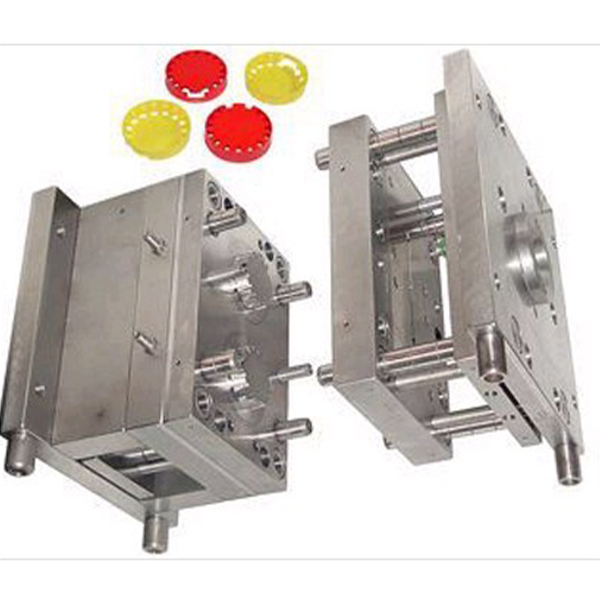

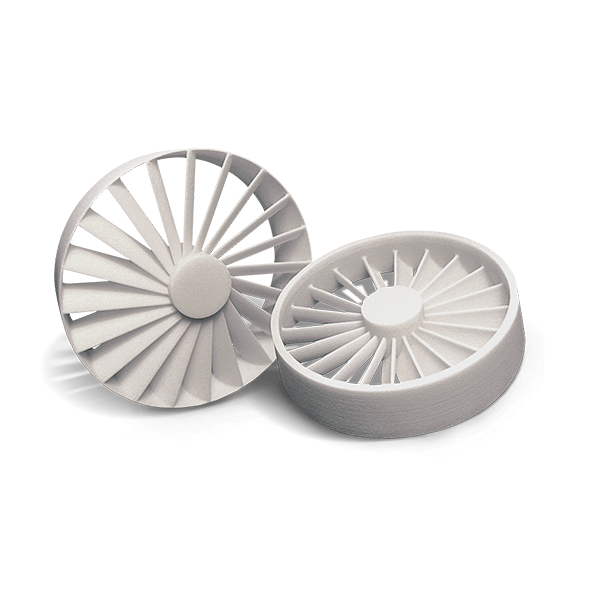

Home Appliance Mould: Tailored Designs for Exceptional Home Appliances

Home appliance mould provides tailored designs to create exceptional home appliances that meet consumer needs. Its versatility allows for the production of a wide range of appliances, from refrigerators to washing machines, with precision and efficiency. With customised mould designs, manufacturers can innovate and differentiate their products, offering features that enhance convenience, energy efficiency, and durability. Home appliance mould ensures consistent quality, enabling the creation of appliances that enhance the lives of consumers and stand out in the competitive market.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ