There is an important tool in the industrial process known as injection molds or inject molds, which are widely used in the manufacture of a large number of products from plastic materials through the process of injection molding. The accuracy of these molds is idle since it is proportional to the quality and efficiency of the end product.

Material Selection injection Moulds Incorporating Tight Tolerances

Materials selection for the fabrication of injection molds and giving them tight tolerances is very critical as it determines their use and life span. Most materials that are used include tool steels, beryllium copper, and aluminum alloy. Each material comes with its unique properties suitable for selected tasks, for instance, tool steels are highly used due to their ability to withstand high volume production rates owing to their durability and abrasion-resistive nature.

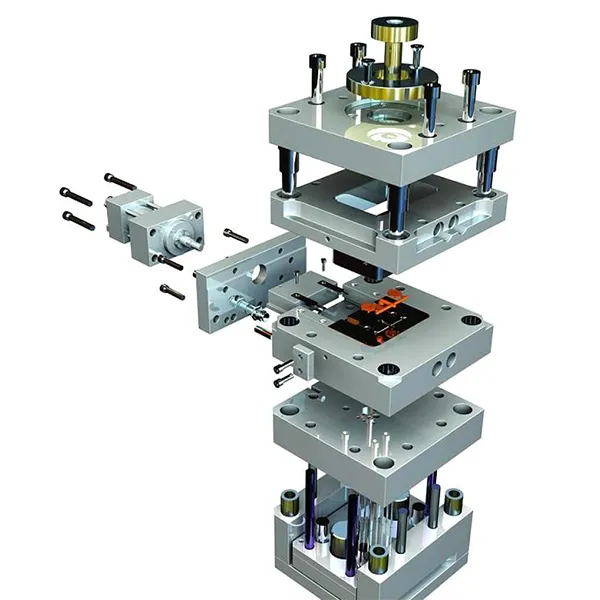

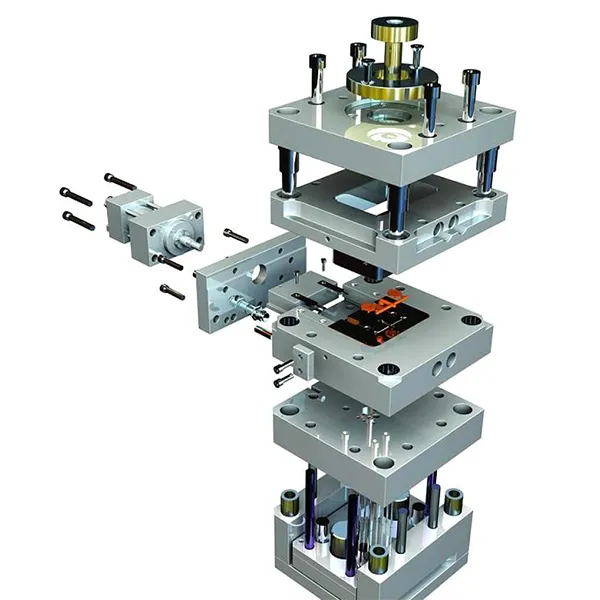

Injection Mould Designing and Construction Image

Producing parts with high precision requires a well-structured and formed mold. Prior to completing the design mold, several issues should be addressed, such as the geometrical characteristics of the part, draft angles, core and cavity location, and channels for part cooling. Shrinkage and warpage of the integral material during the cooling sequence should also be respected to avoid distortions of final parts in relation to the assembly image design. In most cases, however, these parameters can be easily met with the help of advanced simulation software that is now available in the product development phase before actual manufacturing starts.

High-Precision Moulds’ Manufacturing Processes

In order to achieve high precision consistency in the parts, manufacturers employ CNC machining, EDM (Electrical Discharge Machining), or laser cutting, and even injection moulds. Such processes allow for intricate designs of interior corners and edges which are essential for high-level quality molds. Furthermore, additional polishing and texturing operations of the articles that have been cut can further improve the quality of the molded material surface texture quality.

Quality Control and Testing

Here quality control is featured as one of the components of the injection mold building processes where precision is a must. Quality control is performed through thorough testing according to the AS9102 standard, such as the CMM inspection, the first article inspection, and others. At this stage, all inconsistencies detected will be fixed before full-scale manufacturing commences which will be economical in terms of cost and time.

In this case, it may be concluded that the construction of high-precision injection moulds and their design for that matter is science and engineering within the bounds of technology. Such companies as HSM Mould & Tool Inc. provide accurate reliable moulds that will withstand the stiff competition. Known for their emphasis on the latest manufacturing technologies coupled with customer satisfaction, HSM solutions will create a niche in the injection molding industry.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ

Hot News

Hot News